hardness test lab report

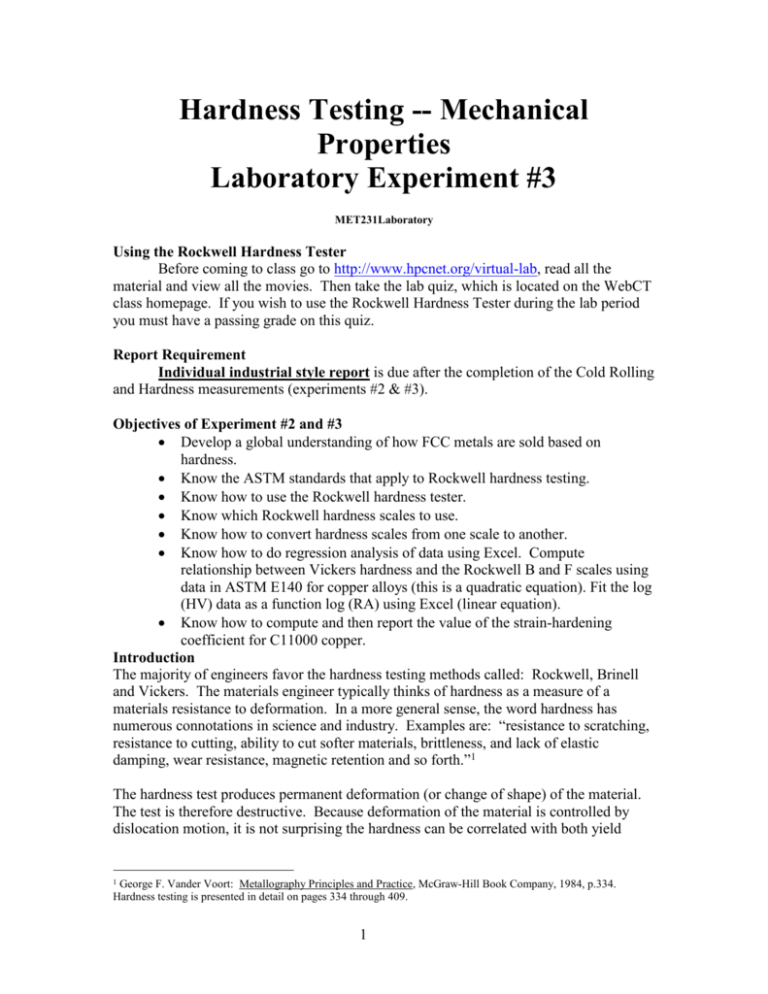

The principal purpose of the hardness test is to determine the suitability of a material for a given application or the particular treatment to which the material has been subjected. EGR 250 Material Science Engineering.

Solution Hardness Test Lab Report Studypool

Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of the material.

. Determine the effective carburizing depth that corresponds to 400 VHN 2. Ad Download or Email Hardness Test Report More Fillable Forms Register and Subscribe Now. Brinell Hardness Test For Brinell hardness test.

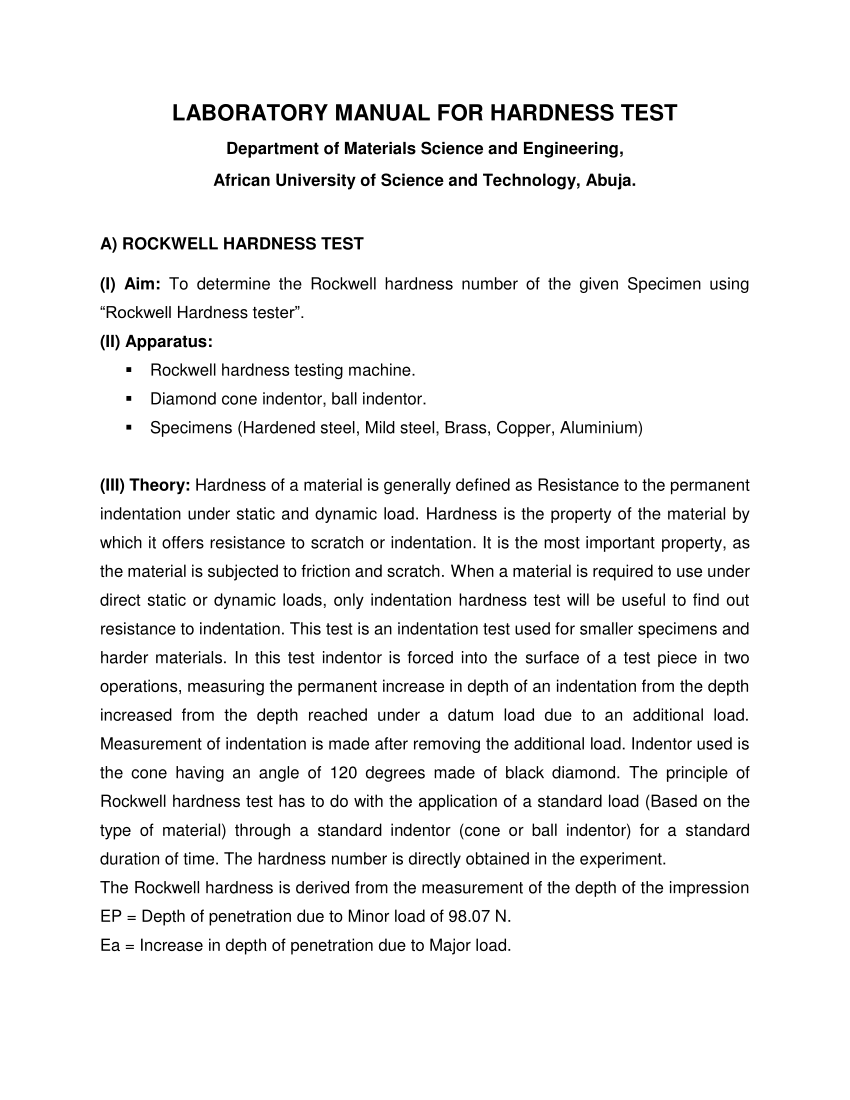

PAGE 1 Definition Defined as the resistance of metal to plastic deformation usually by indentation. LABORATORY MANUAL FOR HARDNESS TEST. Testing can take 30 seconds not counting the sample preparation time.

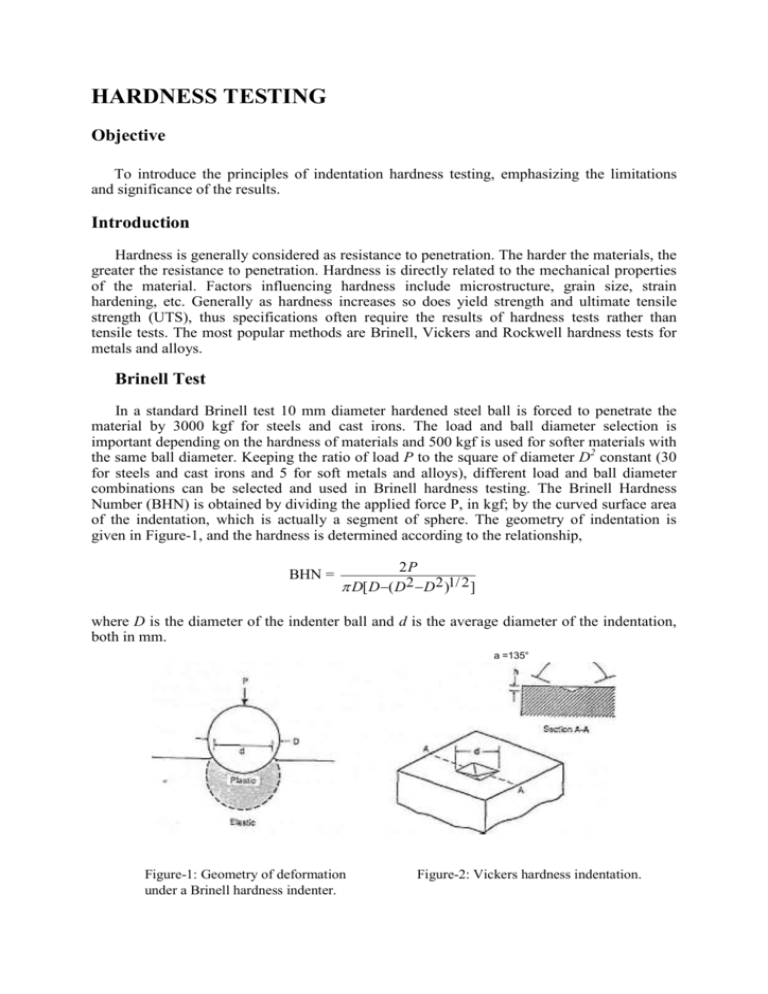

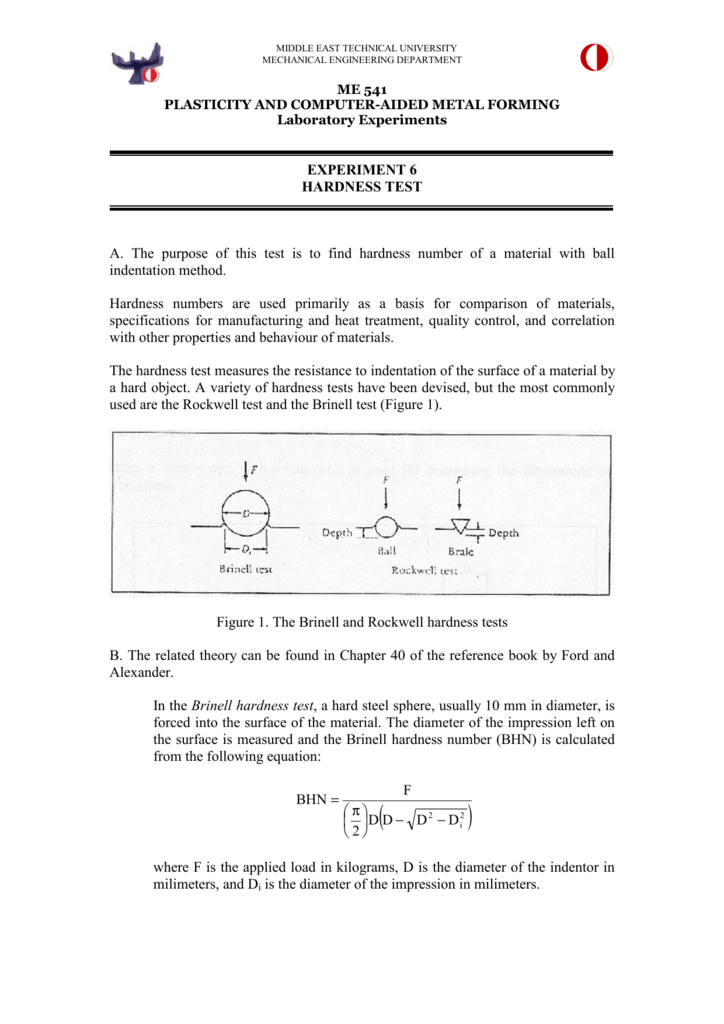

Discussion only those indicated will be answered in the lab report 1. The hardness of materials are test by pressing a steel ball or tungsten carbide ball for a time of 10 to 15 seconds into the surface of specimen by a standard load F kgf. PRACTICAL HARDNESS TESTING MADE SIMPLE 9 3.

3 Procedure The hardness tests are carried out under the supervision of the lab instructor. The Leading Online Publisher of National and State-specific Legal Documents. LAB 4 Technical Report.

Ad Expertise On Every Level To Craft Science Technology Solutions In Life Science. Hardness is defined as a measure of a materials resistance to. April 17 2016 Hardness Test Measurements NAME.

Hardness Test Lab Complete Report. The Vickers hardness test was developed in 1921 by Robert L. The main drawback of the Brinell test is the need to optically measure the indent size.

To investigate the hardness of different metallic materials by using Rockwell hardness test and Brinell hardness test. PdfFiller allows users to edit sign fill and share all type of documents online. Its height was 7 mm and width was 25 mm.

After that the diameter of the indentation d mm is measured when the load is removed. Brinell Hardness Test Lab Report. The purpose of the following experiments is to study the hardness of different types of materials and to understand the significance of this property in materials.

Solving Problems In Life Science By Collaborating With the Global Scientific Community. MATERIAL METHODOLOGY Material and Apparatus Hardness testers. Hardness is the mechanical property of the material which helps him in resisting the plastic deformation of the material.

Brinell hardness test We will measure the hardness of an aluminum plate. ENG60504 PROPERTIES AND APPLICATIONS OF MATERIALS School of Computer Science and Engineering Taylors University LAB. Smith and George E.

The Vickers hardness test follows the Brinell principle in that an indenter of definite shape is pressed. Report on Hardness test. The hardness test is a mechanical test for material properties which are used in engineering design analysis of structures and materials development.

Results List hardness values of Rockwell and Brinell for each specimen. List VHN versus distance from surface for carburized specimen. One of the most popular hardness testing methods Brinell Hardness Number is obtained using a perfectly spherical hardened steel ball of 10 mm pressed against the test surface using a static force of 3000 kg 2942 kiloNewton for at least 10 seconds for steel and measuring.

Hardness Testing Lab Report. Rockwell Hardness Testing Lab Report Sample. Department of Materials Science and Engineering African University of Science and Technology Abuja.

View Lab Report - Hardness Lab Report from ENGR 229 at American University in Cairo. Metal specimen from Experiment 5. Ad Download or Email Hardness Test Report More Fillable Forms Register and Subscribe Now.

Hardness is a measure of a materials resistance to localized plastic deformation eg. Hardness Test Lab Reportpdf - Free download as PDF File pdf Text File txt or read online for free. Report by Ryan Carmichael and Anne Krikorian E59 Laboratory Report Submitted October 7 2008 Department of Engineering Swarthmore College.

Grand V alley State University. The results of our experiment. In this lab Rockwell hardness tests were performed on two unknown steel specimens and one unknown brass specimen with the intent of identifying the metals.

Brinell hardness test is performed to find the hardness typically called. Lab Report Requirements 1. This requires that the test point be finished well enough to make an accurate measurement.

Hardness Testing Experiment 4 ENGR22983 Khaled Atya Hassan 900130977 1 Abstract The objective of this experiment. The specimen Al 2024 which was consist of 38-49 Cu 12-18 Mg 03-09 Mn and Fe Cr Zn Ti in a little amount had been inserted into a furnace set at 500oC approximately 50 minutes for a solution treatment before the lab. However the term may also refer to stiffness or temper or to resistance to scratching abrasion or cutting.

Schematic principles of operation of Vickers hardness machine. CourseMaterials Science For Ce CE 836 Hardness T esting. Plastics deformation can be form the starching compression or due to indentation of any object in the work piece.

View HARDNESS TEST LAB REPORTdocx from ENG 6050 at Taylors University. The materials and the aforesaid property have significant use in civil engineering. MARWAN SHEHATA MOHAMED ZEITOUN NO.

A small dent or a scratchRockwell and Brinell are popular hardness testing methods In a hardness test a small indenter is forced into.

Hardness Test Lab Report Pdf Hardness Tests

Experiment 6 Hardness Test A The Purpose Of This Test Is To

Lab Report 03 Experiment No 02 Rockwell Hardness Test Of A Given Sample Introduction Hardness Of Studocu

Pdf Laboratory Manual For Hardness Test

168547658 Hardness Test Lab Report Pdf Objective To Determine The Hardness Of Various Engineering Studocu

Doc Experiment 3 Hardness Test Min Yih Academia Edu

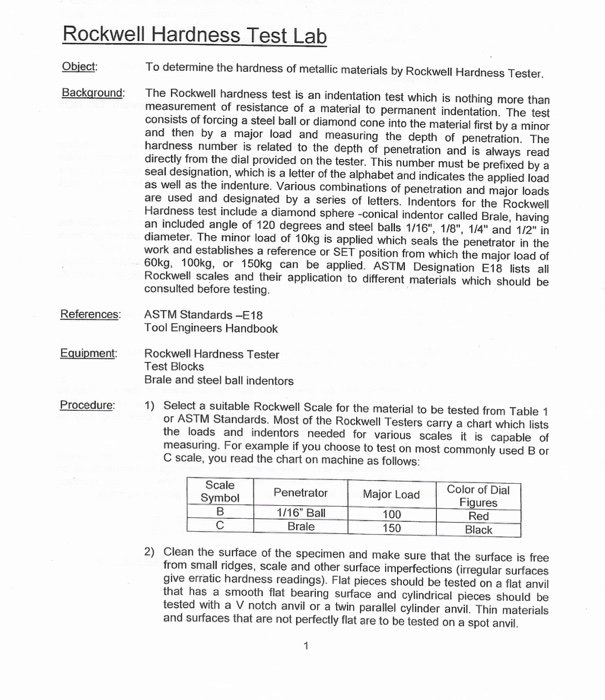

Solved Rockwell Hardness Test Lab Object Background The Chegg Com